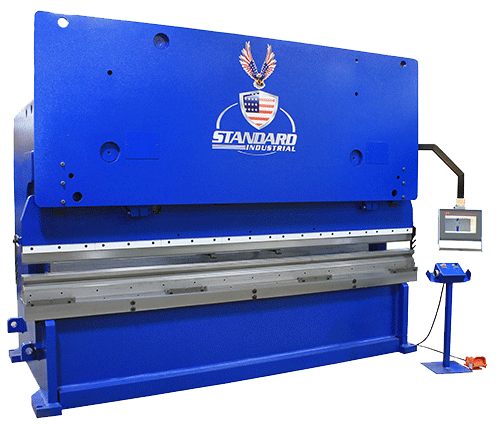

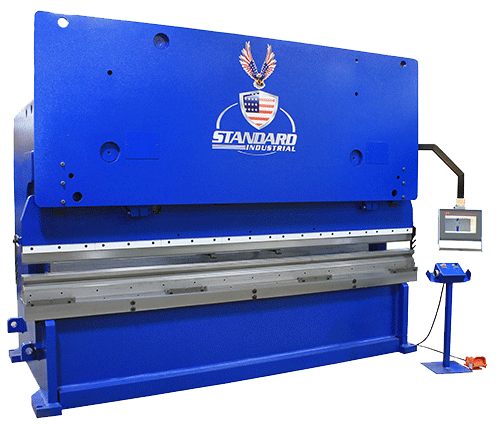

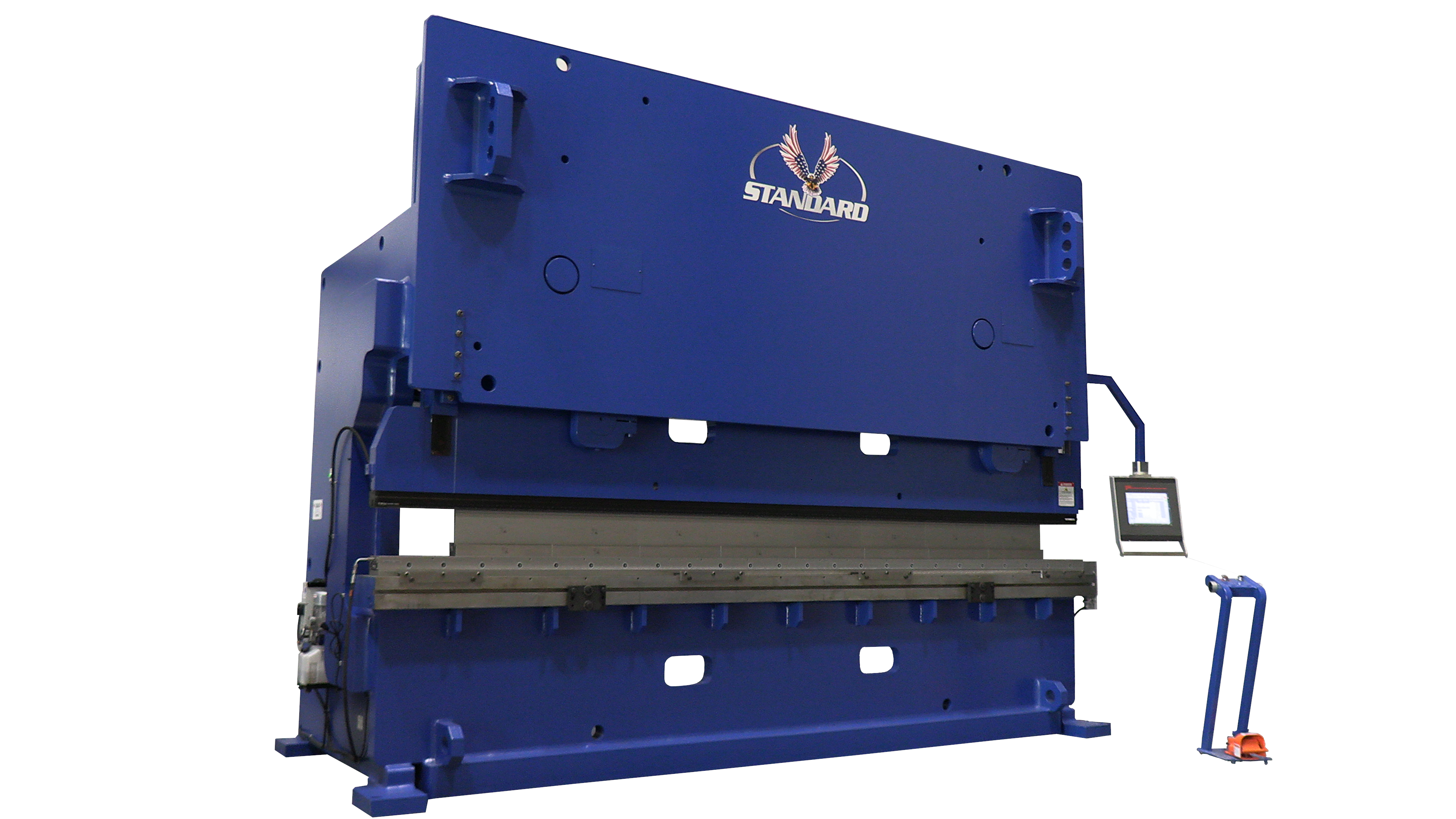

HYDRA-MECHANICAL- AB MODEL

STANDARD FEATURES:

- From Basic to Advanced Ram Control - Simple Non-CNC Limit switch ram control as standard up to optional 10 axis state of the art capability

- Full Tonnage Across the Bed - Precision even tonnage distribution across entire length of the bed and ram

- Ease of Maintenance - The simplest and easiest to maintain hydraulic system on the market

- Press Brake and/or Press Capability - AB brakes can be configured to operate both as a traditional press brake and/or for press applications

- T-Slot - Milled in front edge of bed for left to right support arm movement

- Punching Capability - Can perform punching applications requiring up to 2/3 of the machine's total tonnage

- Made in the U.S.A. - built from non-proprietary parts readily available anywhere in the USA. Proudly owned and operated 100% in the U.S.A.

- Warranty - Our unmatched 5 Year Parts/2 Year CNC/5 Year Limited onsite labor comes standard with every machine

PERFECT COMBINATION OF DURABILITY AND PRECISION:

Our model AB press brakes are available from 100 to 1,500 tons up to 24’. The formidable hydra-mechanical drive system not only provides full tonnage across the bed but also ram repeatability of +,- .001” across the length of the machine.

The AB press brake is specifically designed for full length forming, off-center forming, punching, blanking and most other applications. No CNC or gauging is standard on the model AB brake but all levels of CNC are optionally available. We allow our customers to customize exactly what level of sophistication they require.

From Simple | YOUR CHOICE OF BASIC OR STATE OF THE ART CONTROLS: The AB press brake intentionally comes | To State of the Art |

UNLIMITED PARTS AVAILABILITY:

All Standard Industrial machines come standard with off the shelf components that are available everywhere in North America. We use no proprietary components that force you to come back to us for parts. In your manual you will have the original manufacturer’s name and part number of each component.

WARRANTY:

5 Year Parts + 5 Year Limited Onsite Labor + 2 Year CNC/PLC Warranty. This warranty includes a 5 year limited onsite labor warranty and a 2 year CNC/PLC Warranty. Unlimited lifetime telephone support is included at no charge. If during the first 5 years you have an unresolved issue and telephone troubleshooting has been fully exhausted, we will provide onsite labor to take care of the problem. This warranty is based on 3 shifts a day and 24 hour days. Every machine is also available with our optional 7 Year Extended Warranty that extends the parts warranty by 2 years. NO OTHER MANUFACTURER MATCHES OUR WARRANTY.

PRESS BRAKE AND STRAIGHT SIDE PRESS CAPABILITY:

With our hydra-mechanical drive system providing full tonnage the length of the bed, optionally the model AB press brakes has the ability to be used with traditional press brake tooling and optionally can have either permanent or removable flanges for press die applications. There is more for this unique feature in the options pages.

SERVICE:

We have service capability everywhere in the contiguous United States which can only be expected for a U.S. made machine. We also supply free telephone support for the lifetime of the machine. You talk directly to the people that make your machine.

MANUAL RAM CLAMPING:

American or New Standard Style Ram Clamping Extremely heavy duty, spring loaded die clamps for easy, fast die change. Accepts all American style standard and precision ground tooling. All press brakes can be ordered optionally with Wila (or equiv.) style quick-change powered ram clamping systems and European clamping systems in lieu of manual system.

MANUAL TONNAGE CONTROL:

The model AB press brake comes standard with manual tonnage control that allows the operator to choose tonnage output. Optional programmable tonnage is available with CNC that can be programmed for individual jobs.

EXTREMELY HEAVY DUTY BED CONSTRUCTION:

Includes American Style Die Groove as standard. Incredibly heavy duty lower beams are essential to any well-made press brake to provide the best deflection possible. CNC crowning units are available optionally.

BED FEATURES AND T-SLOT SUPPORT ARMS:

The bed of the AB press brake includes a groove down the center of the brake bed to accept American style tooling. We can also supply European style die holders. A t-slot across the front edge of the brake bed is included to allow the (2) standard 24” works supports to slide left to right the length of the bed.

SAFETY:

The Hand/Foot safety sequence with footswitch is an O.S.H.A. approved 2 hand pedestal control with 3 position footswitch that comes standard on all press brakes. Available optionally are light curtains, Keyence scanning systems and AKAS laser systems. As well as interlocking, physical barriers across back of machine if needed.

24” WORK SUPPORTS:

Each machine comes standard with 24” work supports that can be adjusted vertically to match tool height and can be adjusted left to right the full length of the bed via the included t-slot across the front edge of the bed.

T-SLOT ACROSS FRONT EDGE OF BED:

A 5/8” precision machined t-slot runs the full length of the brake bed. This slot allows the standard 24” support arms to slide left to right the full length of the bed.

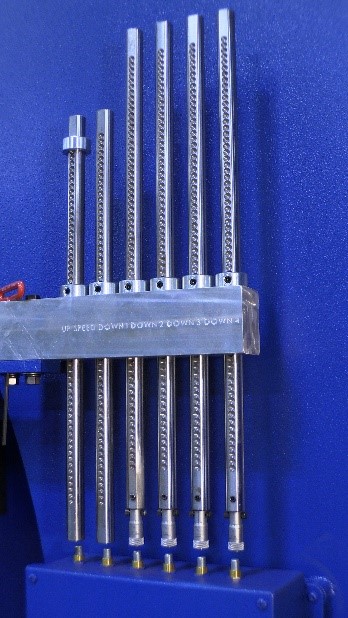

MANIFOLD CENTRALIZED LUBE SYSTEM:

This simple and efficient lubrication system brings all the lube points of the machine to a centrally located area on the back of the press brake. Optionally available is our automatic lubrication system that comes with a warning light when the grease gets low and an auto-shut-off that stops the machine when the reservoir is empty.

HAND/FOOT SAFETY SEQUENCE WITH FOOTSWITCH:

This OSHA approved system for a single operator allows operation with either the included (2) hand palm buttons or palm buttons combined with the footswitch. Optional light curtains, laser systems or scanning systems are also available.

MODEL AB PRESS BRAKE GAUGING OPTIONS

The AB Conventional press brake is perfect for companies who want the choice of either simplified, basic controls or state of the art 2D/3D CNC sophistication. The model AB is essential for any level of production from single shift facilities up to the largest multi-shift corporations in the world.

Regardless of your needs, if you want a dependable machine that lasts for decades but also want to choose your level of control complexity, then the model AB Conventional is your machine.

CNC CONTROL UPGRADES |

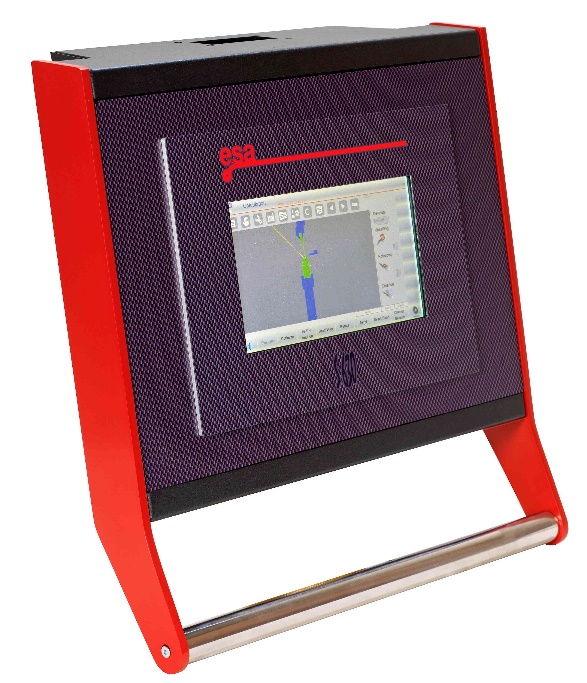

840 2D Touchscreen Control for servo gauges

|  |

630 W/2D Tooling Graphics for servo gauges

|

|

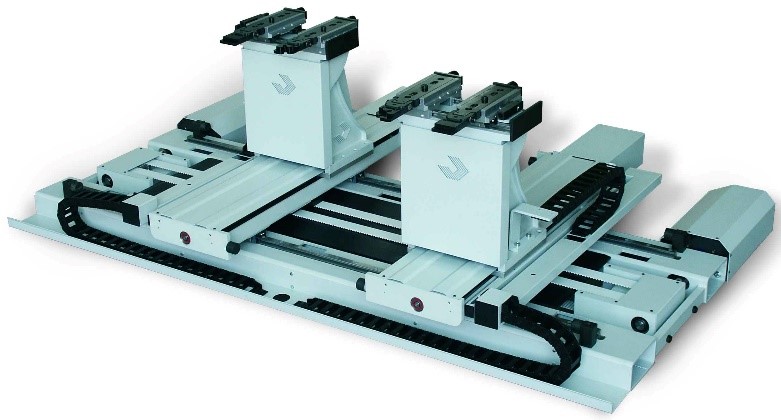

CNC PRECISION SERVO GAUGING SYSTEMS |

The AB press brakes are available optionally with X, R, Z1-Z2 and X-Prime servo gauging systems as well as our full 6 axis gauging system that includes Z1-Z2 + X1-X2 + R1-R2. These extremely heavy duty, precision gauges are available in 29” to 39” travel (special lengths available). All covered by our 5 year parts warranty.

2-4 Axis X+ R (2 axis) or X + R + Z1-Z2 (4 axis)X = Fingers in/out R = Finger up/down Z1-Z2 = Fingers Independently Left/right |  |

5 Axis X + R + Z1-Z2 + X-PrimeX-Prime = Allows 1 finger +,- 3” of center for tapered bends |

|

6 Axis Z1-Z2 + X1-X2 + R1-R26 axis of full articulation Z1-Z2 = Fingers independently left to right X1-X2 = Fingers independently front to back R1-R2 = Fingers independently up and down |

|

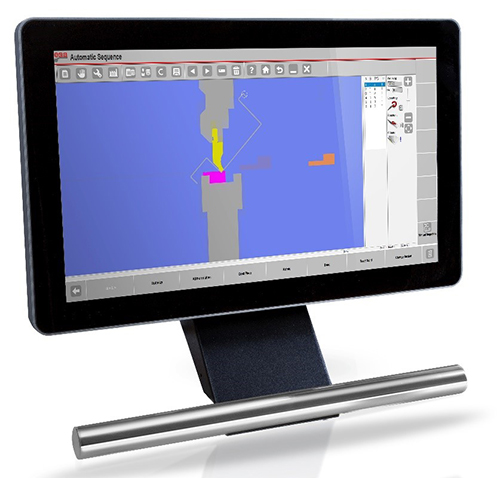

RADAN Radbend (For more information go to www.radan.com)

Offline programming and simulation for press brakes

Radbend from RADAN is the comprehensive offline programming solution for press brakes. Completely integrated with RADAN3D it also provides a full 3D simulation of the bending process.

- Automatic bend sequencing

- Automated tool selection

- Tool setup optimization

- Automatic finger stop positioning

- Customizable reports

- Support for lifting aids and angle measurement systems

Can be integrated with RADAN3D

SIMPLE CNC RAM AND BACKGAUGE CONTROL |

AUTOMEC CNC300 2-3 AXIS CNC Control (www.automec.com)

NOTE: The standard mechanical ram control limit switches will be included as back-up for this CNC control.

|  |

NON-CNC GAUGING | |

|---|---|

FOUR POSITION IN-LINE DEPTH STOP WITH (4) PRE-SET LOWER LIMITS Manual ram control that allows operator to pre-set up to 4 different ram depths/angles by pre-setting the limits on the side of the brake. The operator can then choose from any of the 4 positions from a selector switch located on the standard 2 hand control pedestal out in front of machine. |  |

GO-TO, POWER BACKGAUGE

|  |

LIGHT CURTAIN WITH FOOTSWITCH

- Floating blank key-switch included, some programmability. Side barriers included to completely protect throat area of machine. 1 year warranty.

LASER GUARDING SYSTEM

- Wraps lasers around punch to allow operator closer to pinch-point and still be O.S.H.A. approved. 1 year warranty.

COMPLIANCE OPTIONS INCLUDING UL LISTING, CSA, ZED

ADDITIONAL FOOTSWITCH AND PEDESTAL CONTROL FOR 2nd OPERATOR

LOW SPEED RETRACT

- Ram returns in slow press speed for handling of large work pieces.

SAFETY GUARDING FOR REAR OF PRESS BRAKE

- Comes with swinging gates and interlocking system for shut down while open. Custom guarding systems available.

SUPPORT ARMS AND ACCESSORIES

T-SLOT SUPPORT ARMS

All brakes come standard with (2) 24" basic work supports. Optional T-slot support arms have precision t-slot bars added to set optional gravity stops. Available in 24”, 36” or 48” and with imbedded scales.

QUICK RELEASE LINEAR WORK SUPPORTSQuick-change, quick-disconnect style support arms with heavy duty, smooth transition roller guides for easy arm movement. Multiple adjustment points on arms for super precision placement. |  |

CNC SHEET ASSISTSWhen operator safety and precision part handling are a priority, our CNC sheet assists are the solution. CNC controlled for precision part following and available for any level of production. |  |

TOOLING

Available on all 3 models of press brakes are single V, Four Way Conventional tooling plus Wilson/Wila Precision Ground, Segmented tooling. All tooling requirements available.

MANUAL CROWNING

For the most precision requirements, manual crowning allows the operator to set the desired deflection.

RAM AND BED CLAMPING SYSTEMS

Quick-change, powered clamping systems for upper and lower tooling providing you the quickest set up times possible. Perfect for American or New Standard style of tooling. Lower clamping available with or without crowning.

AMERICAN AND NEW STANDARD PRECISION TOOLING

Precision ground to +,- .0004” and hardened at wear points, segmented tooling is the answer for quality and fastest set up times.

CNC CROWNINGFor the most precision requirements, CNC crowning allows the operator to program the desired deflection for each job reducing set up time. |  |

RAM AND BED CLAMPING SYSTEMSQuick-change, powered clamping systems for upper and lower tooling providing you the quickest set up times possible. Perfect for American or New Standard style of tooling. Lower clamping available with or without crowning. |

|

AMERICAN AND NEW STANDARD PRECISION TOOLINGPrecision ground to +,- .0004” and hardened at wear points, Wila segmented tooling is the answer for quality and fastest set up times. |

|

TRADITIONAL PRESS BRAKE AND STRAIGHT SIDE PRESS CAPABILITYWith our hydra-mechanical drive system providing full tonnage the length of the bed, the model AB press brakes have the ability to be used with traditional press brake tooling and optionally can have either permanent or removable flanges for press die applications. Removable flanges on the bed and/or ram will allow you to utilize both conventional press brake tooling as well as press die applications as needed. Permanent bed and ram flanges will allow a wide array of press die applications for substantially less cost of a traditional straight side press. |

|

OPERATIONAL PREFERENCE CONTROLS

AUTO RETURN OF RAM

Normal operation of ram requires operator to release footswitch to allow ram to return to upper limit. This option makes the ram return automatically even if footswitch is still depressed.

DECOMPRESSION SYSTEM

REQUIRED FOR BOTTOMING APPLICATIONS—allows oil pressure to bleed off to reduce shock to hydraulic system.

AUTOMATIC LUBRICATION SYSTEM (air power required)

Automatically pumps EP-1 grease through lubrication system via a timed system. Also includes flow adjustable injectors. Includes auto-shutoff with warning light when reservoir is empty.

EXTENDED WARRANTY

This optional warranty extends the standard 5 year parts warranty by 2 years. Includes:

- 7 year parts in lieu of standard 5 year parts warranty

- 2 year PLC and CNC warranty

- 5 year onsite limited labor warranty

EXTRA STROKE/EXTRA OPEN HEIGHT/DEEPER THROATS/HORN EXTENSIONS

All our machines can be tailor made to your exact needs

ADDITIONAL OPTIONS

Robotic interfaces

Longer T-slot support arms

Conventional tooling

Custom (single) paint color (sample required)

| Product Number | Shipping Weight | Forming / Punching | Bed/Ram Length | Between Frames |

|---|---|---|---|---|

| AB100-6 | 12,000 lbs | 100 / 66 Tons | 6 ft | 4'-5" |

| AB100-8 | 15,000 lbs | 100 / 66 Tons | 8 ft | 6'-5" |

| AB100-10 | 19,000 lbs | 100 / 66 Tons | 10 ft | 8'-5" |

| AB100-12 | 21,000 lbs | 100 / 66 Tons | 12 ft | 10'-5" |

| AB100-14 | 26,000 lbs | 100 / 66 Tons | 14 ft | 12'-5" |

| AB100-16 | 32,000 lbs | 100 / 66 Tons | 16 ft | 14'-5" |

| AB100-20 | 50,000 lbs | 100 / 66 Tons | 20 ft | 18'-5" |

| AB150-8 | 19,000 lbs | 150 / 100 Tons | 8 ft | 6'-5" |

| AB150-10 | 22,000 lbs | 150 / 100 Tons | 10 ft | 8'-5" |

| AB150-12 | 26,000 lbs | 150 / 100 Tons | 12 ft | 10'-5" |

| AB150-14 | 31,000 lbs | 150 / 100 Tons | 14 ft | 12'-5" |

| AB150-16 | 38,000 lbs | 150 / 100 Tons | 16 ft | 14'-5" |

| AB150-20 | 72,000 lbs | 150 / 100 Tons | 20 ft | 18'-5" |

| AB200-12 | 32,000 lbs | 200 / 135 Tons | 12 ft | 10'-5" |

| AB200-14 | 45,000 lbs | 200 / 135 Tons | 14 ft | 12'-5" |

| AB200-16 | 50,000 lbs | 200 / 135 Tons | 16 ft | 14'-5" |

| AB200-20 | 85,000 lbs | 200 / 135 Tons | 20 ft | 18'-5" |

| AB250-12 | 40,000 lbs | 250 / 165 Tons | 12 ft | 10'-5" |

| AB250-14 | 50,000 lbs | 250 / 165 Tons | 14 ft | 12'-5" |

| AB250-16 | 56,000 lbs | 250 / 165 Tons | 16 ft | 14'-5" |

| AB250-20 | 85,000 lbs | 250 / 165 Tons | 20 ft | 16'-5" |

| AB325-12 | 49,000 lbs | 325 / 215 Tons | 12 ft | 10'-5" |

| AB325-14 | 60,000 lbs | 325 / 215 Tons | 14 ft | 12'-5" |

| AB325-16 | 66,000 lbs | 325 / 215 Tons | 16 ft | 14'-5" |

| AB325-20 | 100,000 lbs | 325 / 215 Tons | 20 ft | 16'-5" |

| AB400-12 | 58,000 lbs | 400 / 265 Tons | 12 ft | 10'-5" |

| AB400-14 | 67,000 lbs | 400 / 265 Tons | 14 ft | 12'-5" |

| AB400-16 | 80,000 lbs | 400 / 265 Tons | 16 ft | 14'-5" |

| AB400-20 | 110,000 lbs | 400 / 265 Tons | 20 ft | 16'-5" |

| AB500-12 | 70,000 lbs | 500 / 300 Tons | 12 ft | 10'-5" |

| AB500-14 | 80,000 lbs | 500 / 300 Tons | 14 ft | 12'-5" |

| AB500-16 | 87,000 lbs | 500 / 300 Tons | 16 ft | 14'-5' |

| AB500-20 | 129,000 lbs | 500 / 300 Tons | 20 ft | 16'-5" |

| AB600-12 | 87,000 lbs | 600 / 400 Tons | 12 ft | 10'-5" |

| AB600-14 | 97,000 lbs | 600 / 400 Tons | 14 ft | 12'-5" |

| AB600-16 | 108,000 lbs | 600 / 400 Tons | 16 ft | 14'-5" |

| AB600-20 | 150,000 lbs | 600 / 400 Tons | 20 ft | 16'-5" |

| AB700-14 | 112,000 lbs | 700 / 465 Tons | 14 ft | 12'-5" |

| AB700-16 | 135,000 lbs | 700 / 465 Tons | 16 ft | 14'-5" |

| AB700-20 | 180,000 lbs | 700 / 465 Tons | 20 ft | 16'-5" |

| AB1000-14 | 160,000 lbs | 1000 / 600 Tons | 14 ft | 12'-5" |

| AB1000-16 | 170,000 lbs | 1000 / 600 Tons | 16 ft | 14'-5" |

| AB1000-20 | 195,000 lbs | 1000 / 600 Tons | 20 ft | 16'-5" |